BWT supports you

Innovation for water conservation

Through its innovations and locations, BWT is committed to limiting its carbon footprint, and that of its customers, as with the OPTIVAP

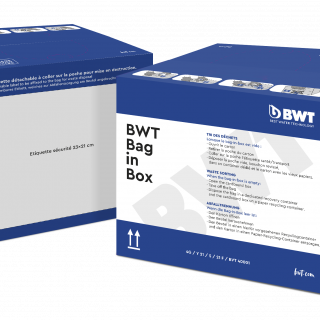

concept.Behind the Bottle Free Zone approach and its factories in France, BWT reduces the carbon footprint of its formulated products thanks to its unique and innovative BAG in BOX concept, and limits the number of on-site visits by its technicians with BLUWELL, a remote monitoring application for industrial installations.

BWT ECO-MX (on-site production of disinfectant solution) limits CO2 emissions caused by transport and delivery of chemicals (over 36 tonnes saved per year).