Green hydrogen

Hydrogen is essential for renewable and sustainable energy, and is particularly crucial where alternatives to fossil fuels are limited. Its production must be environmentally friendly to remain sustainable, requiring ultrapure water for high-quality hydrogen. We offer complete, integrated solutions, including the design of environmentally-friendly water treatment systems for the production of green hydrogen.

Pure water production

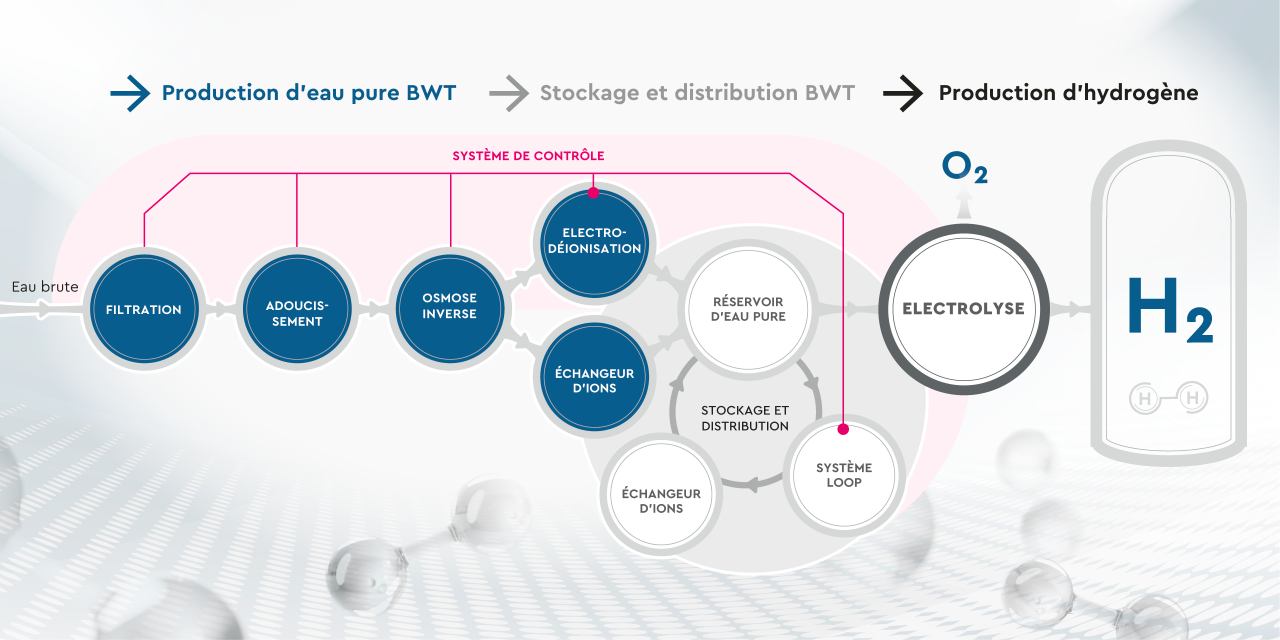

Various methods exist for producing hydrogen, including hydrocarbon or biomass production. However, the most environmentally-friendly method is electrolysis, which separates water into hydrogen and oxygen using clean energy. To do this, the water, which is essential for producing green hydrogen, must be ultrapure. Water quality, influenced by regional variations and the concentration of minerals in groundwater or surface water, is crucial. Prior to electrolysis, minerals must be removed in demineralisation facilities to prevent salt deposits on electrolyser membranes and electrodes.

To achieve this, a complete treatment plant is required, consisting of several pieces of equipment adapted in series for this purpose. These are selected and combined according to the process chosen and the quantitative requirements of the users. In this way, it is possible to achieve better performance more quickly, thanks to tried-and-tested solutions.

BWT WHy: Water for Hydrogen by BWT

The know-how of an expert in ultrapure water production

The chain system recommended by BWT for water treatment in hydrogen production:

- BWT softening system

- BWT reverse osmosis unit

- BWT electrodeionization unit

- BWT loop system / Closed circuit treatment with integrated ion exchanger

- BWT control system

Standard performance:

- Production of quality water with a conductivity of < 5 µS/cm to 0.1 µS/cm

- Standard flow rates from 200 to 10,000 l/h

Filtration

Media or membrane filtration to remove most of the colloids and suspended solids from the incoming water.

Softening

Removing limescale from industrial water: protection, performance and lifespan of industrial infrastructures.

Reverse osmosis

High-pressure membrane purification system retaining all salts.

Electrodeionisation

Continuous production of ultra-pure, chemical-free water.

Support from A to Z

Our expertise in industrial projects, from design to commissioning

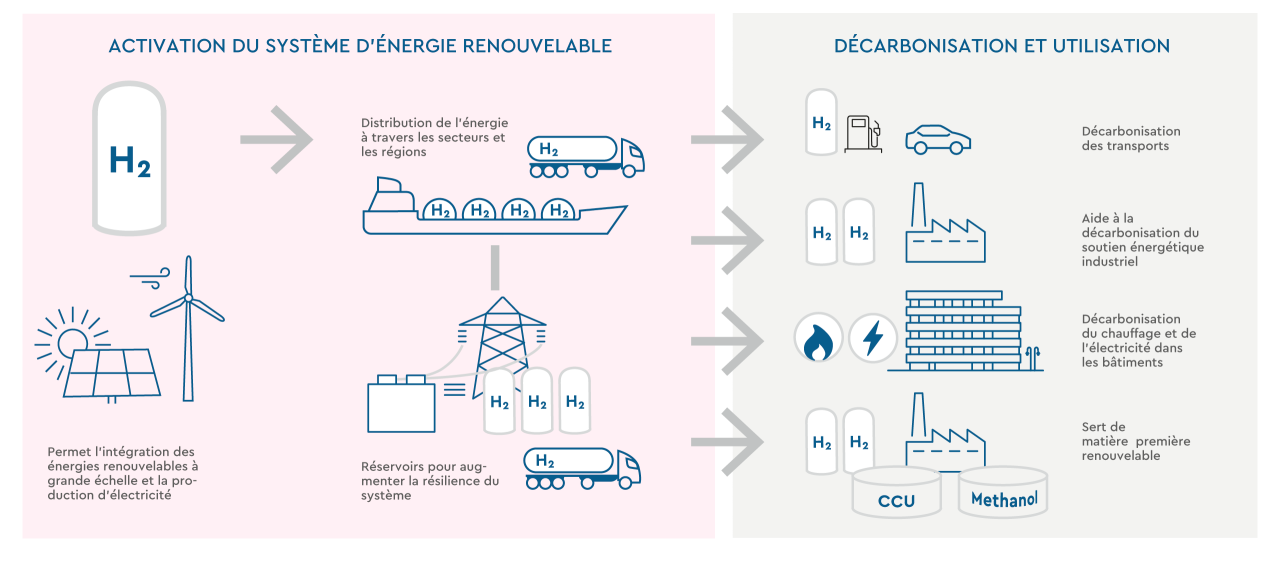

Possible applications for hydrogen

In principle, hydrogen could replace fossil fuels in the future. Major car manufacturers have discovered the potential of fuel cell technology. Many hydrogen-powered trucks, cars and buses are now on the road. Fuel cells, an innovative technology, are going beyond automotive use to supply homes with electricity and heat. Green hydrogen is still essential for reducing CO2 emissions in the long term. Green hydrogen is the only viable option if we want to reduce our CO2 emissions in the long term.