Industrial canning

Reuse of wastewater, guaranteed quality of surface discharges

Part of the Eureden group, the D'Aucy Le Faouët site (56) is one of the company's largest vegetable canning plants, with production of 100,000 tonnes a year. Reflecting the Group's commitment to preserving resources in general, and water in particular, this industrial site in Morbihan, located in a rural setting and bordered by a river, has long been committed to reducing the environmental impact of its activities.

Against this backdrop, in 2012 the D'Aucy Le Faouët site embarked on a project to optimise the water cycle, which culminated in 2018 with the opening of a 35 m³/h WWTP in the immediate vicinity of the canning factory. Dedicated to the treatment of effluent and plant waste from the site, the WWTP opened the way for the reuse of some of the wastewater from the industrial process.

The issues

Reusing waste water

Previously supported by BWT France and equipped with BWT ECO-MX solutions for the steam boiler and air cooling towers, and BWT AQASter to protect the sterilisation and pasteurisation equipment, the operating teams at the D'Aucy Le Faouët site decided in 2018 to finalise their water cycle management project, which began in 2012, with the implementation of a WWTP.

For the company, the aim was twofold: to preserve water resources by reusing them as much as possible in its industrial processes, but also to return the cleanest possible water to the river into which the effluent is discharged, without any risk to the local aquatic flora and fauna

The solution

Reverse osmosis recycling

As part of its wastewater reuse strategy, the site inaugurated a 35 m³/h WWTP in 2018. The water treated in this way, which is used to pre-wash vegetables in cold areas or to wash floors, has the disadvantage of a high chloride content, which is incompatible with the site's stainless steel equipment, leading to a direct risk of irreversible damage to the stainless steel.

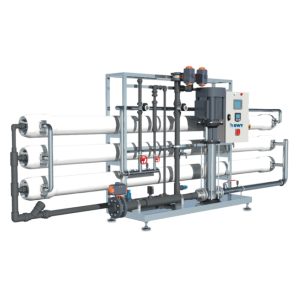

To meet the need for complete potabilisation of this purified water with a view to its reuse, the BWT France teams proposed to the site operators the design of a customised BWT SIGMA osmosis unit. Made from a special stainless steel alloy to deal with the problems of mineral content, the reverse osmosis equipment is capable of producing up to 15 m³/h. Thanks to this solution, the osmosis water used is of a higher quality than the drinking water standard.

Able to support its customers from start to finish, BWT France also helped D'aucy Le Faouët with the administrative and financial aspects. In this context, the Loire-Bretagne Water Agency, which had already contributed 30% of the costs of the WWTP, provided the site with funding corresponding to 35% of the costs of installing the reverse osmosis equipment

Results

Customer testimonial

Find out how we support our customers in their industrial water treatment.

“In addition to the manufacture and installation of the equipment, the support provided by BWT France's teams with regard to the administrative aspects was particularly appreciated, and the result was commendable, with a subsidy of 35% of the installation costs provided by the Loire-Bretagne Water Agency," explains Michaël Le Moal, manager of the D'aucy Le Faouët site. “This partial contribution will further reduce the payback period.”

"In the long term, the support provided by BWT France's technicians is also very reassuring: they monitor the equipment regularly, both for sterilisation and reuse. Analytical checks are carried out every month, and a maintenance visit is made every quarter.

Products used

BWT ECO-MX

Generator of fresh, continuous disinfectant solution, in situ, by salt electrolysis

BWT AQASTER

Turnkey solution for sterilising and pasteurising packaging