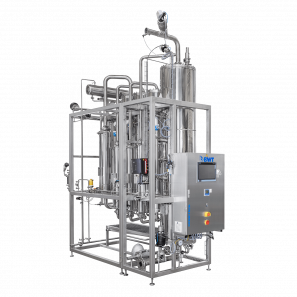

The 360° life cycle

To ensure that your installations run smoothly, BWT offers a complete range of services for all its equipment and products, from qualification and validation of requirements and studies to team training, in a spirit of partnership.

AQA CONFIDENCE meets specific needs:

- Customised maintenance plan

- Modular and flexible solution

- Compatible with third-party solutions

- All services from a single source

- Ideal preparation for audits and inspections

- Maximum long-term availability

9 pages, langue french, PDF (3.15 MB)