Cooling towers

Combating scaling, corrosion and bacterial growth

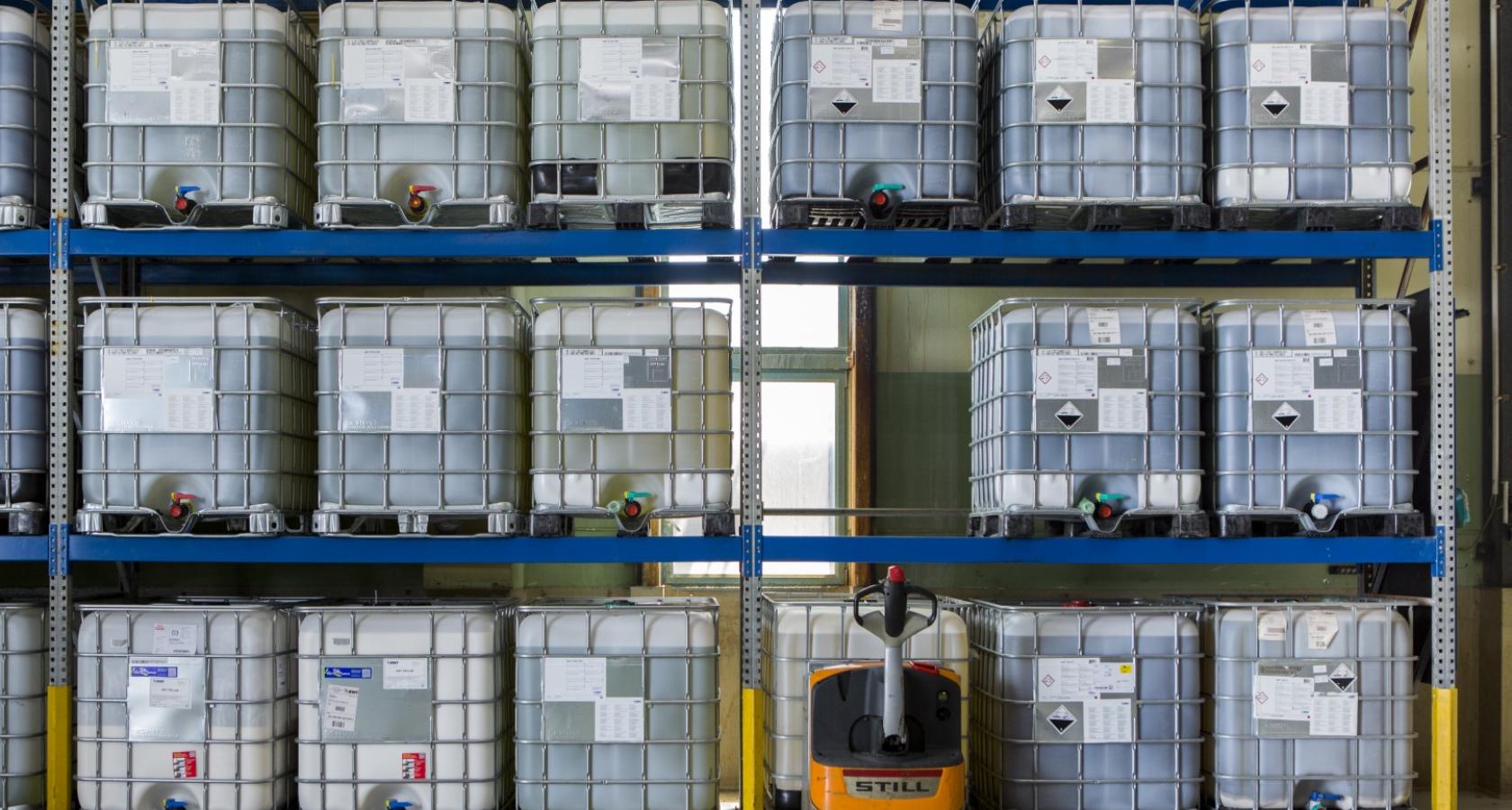

BWT's range of formulations for cooling towers targets two main objectives: firstly, to protect the installations themselves, in particular against scaling and corrosion.

Secondly, to combat bacterial growth (biofilm), in particular the risk of proliferation and dispersion of legionella in the cooling tower environment (classified under heading 2921 of the ICPE nomenclature).