Since 2005, energy saving certificates (ESCs) have been used to finance operations designed to reduce energy consumption, and therefore improve energy efficiency, in a wide range of sectors, including industry and the residential sector. Despite the long history of the certificate system, successive changes have not made it any easier to understand. In the specific context of industrial water treatment, changes to installations designed to reduce energy consumption are eligible for energy saving certificates.

What is an energy saving certificate?

Introduced by French law no. 2005-781 of 13 July 2005, known as the “Programmation fixant les Orientations de la Politique Énergétique” [Programme setting the guidelines for energy policy] (POPE), ESCs are a scheme designed to enable energy savings to be made (energy retrofitting work such as loft insulation) in a wide range of sectors: residential, service, industry, agriculture, networks and transport.

Every three years, the government requires energy suppliers and fuel distributors (the obligated parties) to achieve a certain volume of energy savings (the obligation) for the beneficiaries (households, local authorities, businesses, etc.). All of these are represented by Energy Savings Certificates.

In practical terms, this means that obligated parties (or eligible parties) finance energy-saving or retrofitting work aimed at reducing the energy consumption of eligible parties. To date, 199 standardised operations are in force in six sectors: residential buildings, service buildings, networks, agriculture, industry and transport. The financing of specific operations and targeted actions (training, information, innovation and the fight against fuel poverty) as part of the ESC programmes, also make it possible to generate an ESC.

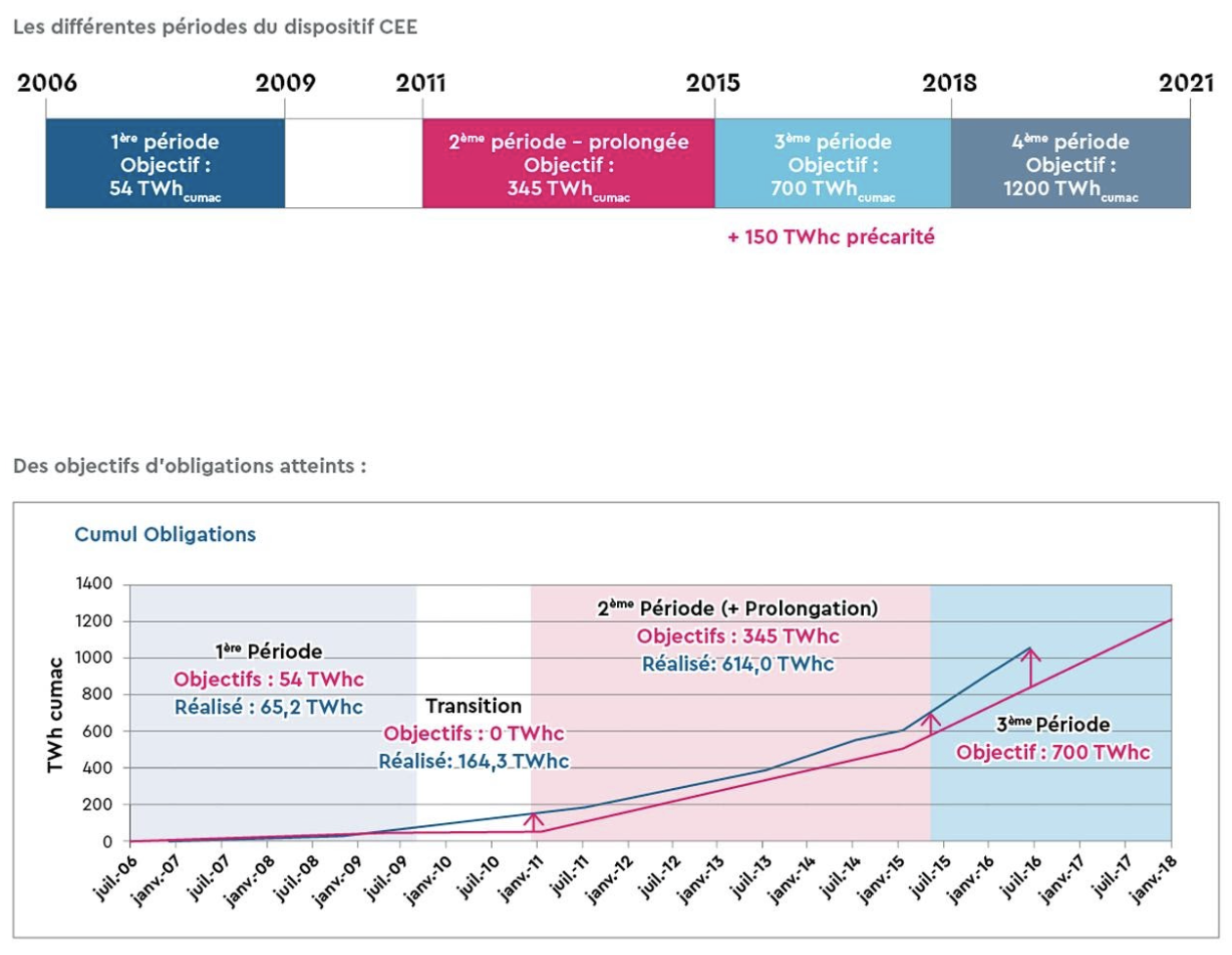

Over the first two periods provided for by the law, the objectives were largely exceeded: from 2006 to 2009, for a savings objective of 54 TWh Cumac, 65.2 TWh Cumac were achieved. Over the second period (extended by two years: 2011-2015), 614 TWh Cumac were achieved (compared with 345 forecast). This trend is set to continue in subsequent periods, with extensions expected to extend the scheme beyond 2021.

What does kWh cumac, the unit of measurement for ESC, mean? How are ESCs issued?

The unit of measurement for ESCs is the kWh Cumac (kWhc), which stands for “cumulative, discounted”. In other words, for a given operation, the savings generated are cumulated over the life of the operation and discounted at an annual rate of 4%.

The advantage of using this unit of measurement is that, on the one hand, it takes into account the entire life cycle of the operation. But on the other hand, it also takes into account the increase in energy costs over time, so as not to depreciate older operations.

ESCs are issued by the ESC National Division (DGEC) once the work associated with the target operation has been carried out. 1 ESC = 1 kWhc is transferred to an electronic account in the national Emmy register.

ESCs are valid for 10 years, and can be increased under energy performance contracts (EPC), or even doubled in non-interconnected zones (NIZ), i.e. areas not connected to the continental electricity grid.

What options do obligated parties have for producing ESCs

? The law provides obligated parties with five options for meeting their ESC obligations:

- Incentivising ESC-eligible energy-saving operations: this is the most direct option.

- Making a financial contribution to ESC programmes: training, information, innovation or the fight against fuel poverty.

- Buying ESC on the market: the Emmy national register offers the option of trading ESCs.

- Delegating their obligation to another obligated party.

- Paying a penalty of €15/MWhc.

Industry: what equipment is eligible for ESCs

? While reducing energy consumption is of course the main objective for manufacturers, the financial assistance they receive under the ESC scheme is often also an opportunity to improve productivity while modernising their production facilities.

A wide range of equipment is eligible for ESCs as part of industrial processes, and is set out in standardised operation sheets:

- IND-UT-125 Heating: high-performance water treatment on a steam production boiler, economiser on the gaseous effluents from a steam production boiler, micro-modulating burner on an industrial boiler.

- IND-UT-102 Motorisation: electronic speed variation system on asynchronous motor, IE2 / IE3 / IE4 class high-efficiency motor, synchronous motor-inverter with permanent magnets or reluctance, high-performance transmission system.

- IND-UT-116 Refrigeration: high-efficiency refrigeration condensing system, regulation system on a refrigeration production unit to provide a floating LP, regulation system on a refrigeration production unit to provide a floating HP, heat recovery system on a refrigeration production unit, heat recovery system on an air-cooling tower.

- Others:

- IND-BA-112: heat recovery system on a cooling tower

- IND-UT-121: insulation blankets for singular points

- IND-UT-135: Free cooling using cooling water to replace a chiller.

Industrial companies: potential support

In addition to the financing of eligible operations, the question of support for industrial companies often comes into play. Today, most beneficiaries can turn directly to the obligated parties who have set up a support system.

This is the case, for example, with EDF, which has set up a national support system, backed up by regional ESC partner relationship managers This support is comprehensive, from the study of eligible operations to the collection of the energy saving premium, including the calculation of the cost of the operation and the potential energy savings over the entire life cycle of the equipment concerned.

Other players can take over from manufacturers where appropriate, such as delegated contractors (companies specialising in the scheme), manufacturers, equipment suppliers or installers who have signed a contract with a mandatory contractor (as in the case of BWT for IND-UT-125), and design offices.

Here are some practical examples

In the specific context of water treatment in industry, eligible operations are aimed at reducing consumption of water, energy and packaging products. And this is true from the very first day of implementation.

In the dairy industry, for example, the installation by BWT of a reverse osmosis system for a boiler enabled the beneficiary company to reduce its consumption of treatment products by 63%, representing savings of €9,700, and gas consumption by 7%, a saving of €40,000. At the same time, blowdown was reduced by 80%.

Depending on the cost of the operation and its financing (which can be up to 100%), the return on investment can be particularly rapid (or even immediate) and, in all cases, limited to a few months.

Another example is Brasserie Licorne which, by optimising the water treatment of its steam boiler, has reduced its gas consumption by 500 MWh per year and its water consumption by 15 m³ per day. Take a look at the feedback.

In conclusion, remember that, since 1 January 2019, EU ETS (European Union Emission Trading Scheme) sites, i.e. those subject to CO2 emission quotas, are now eligible for ESCs for improvements, enabling them to limit these emissions. For BWT, this is a key area of support for its industrial customers in 2020 and 2021, as the fourth period has been extended to the end of 2021.

Sources: ADEME and workshop organised by BWT with speakers: Julie Pisano from ATEE - Club C2E, Nathalie Barnier from EDF, Emmanuelle Le Guern from BWT.